DBDG-4A Non-stop Turret Rewinder

Specification

| model | 330 | 450 | 570 |

| Application | Printed labels and blank labels rewinding | ||

| Max rewinding diamete | 350mm | 400003 | |

| Max widt | 330 | 450mm | 570mm |

| Min rewinding width | 40mm | ||

| Total power | 8kw | 14kw | 16kw |

| Power supply | 3PH+N+PE | ||

| Machine dimension | 1.45X3X1.7m | 1.45X3.4X1.7 | 1.45X3.6X1.7m |

| Machine weight | 2t | 2.5t | 2.7t |

| Air pressure | 0.8MPa | ||

| Max speed | 1-inch rewinding shaft : 90m/min | ||

| 1.5-3 inch rewinding shaft:120m/min | |||

Features

- ◪ Fully automatic 4-shaft turret type non-stop rewinder, the rate of achieving paper success is up to 100%. And it ensures that the tension stability of equipment in the production stage regardless of the jog, speed increase, speed reduction, emergency, to realize the best condition of the printing machine.

- ◪ The system adopts the world-famous brand Bosch Rexroth, which provides intelligent production solutions. It adopts full servo closed-loop tension control and equips with a bowl feeder, conveyor, to realize online non-stop rewinding.

- ◪ The rewinder can be connected to rotary die cutting, slitting machines, flexographic printing machines, and other equipment. It is equipped with a 1-inch 1.5-inch 3-inch quick-release airshaft. The rewinder does not require manual mechanical adjustment when changing the size of different shafts, its system automatically adjusts the size of the shafts to reduce the labor force for intelligent production.

Machine Picture

Videos link

Videos link:

turret rewinder: tail label sealing

Turret rewinder: Tea/coffee label rewinding 30*25mm*7

DBDG-4A 330 glue type turret rewinder

Turret rewinder in line with packing machine

(Turret Rewinder)Customer feedback in Saudi Arabia

DBDG 4B Glueless type auto 4 shafts turret rewinder

DBDG 4A turret rewinder in line with flexo printing machine

DBDG 450 4 shafts turret rewinder with our matching unwinder and slitter

DBDG Turret rewinder in line with double station rotary die-cutting machine

Feedback of DBDG 4A Turret rewinder 570mm width type

Auto Bowl feeder of turret rewinder by vibrating

Application

Machine Features

- Fully automatic 4-shaft turret type non-stop rewinder, the rate of achieving paper success is up to 100%. And it ensures that the tension stability of equipment in the production stage regardless of the jog, speed increase, speed reduction, emergency, to realize the best condition of the printing machine.

- The system adopts the world-famous brand Bosch Rexroth, which provides intelligent production solutions. It adopts full servo closed-loop tension control and equips with a bowl feeder, conveyor, to realize online non-stop rewinding.

- The rewinder can be connected to rotary die cutting, slitting machines, flexographic printing machines, and other equipment. It is equipped with a 1-inch 1.5-inch 3-inch quick-release airshaft. The rewinder does not require manual mechanical adjustment when changing the size of different shafts, its system automatically adjusts the size of the shafts to reduce the labor force for intelligent production.

Detail Information

– Unwinding Unit

For off-line operation, we could offer an option of a space-saving 1000mm diameter braked unwind unit, with an integral material roll lift, electronic web guide, adjustable splice table with clamps, and auto-lift scissor slitting unit, complete with six sets of rotary knives. For in-line operation, we have an online encoder of the Megawa brand to synchronize with your machine perfectly.

– Automatic paper core loading system

The automatic paper core loading system includes a bowl feeder and conveyor. The conveyor connects the bowl feeder and the main part. The bowl feeder adopts a shaking design to adjust the paper core position keeping each core running horizontally. There is a Panasonic sensor at the front side of the conveyor, the function is to sensor the situation of paper cores on the conveyor, if that is full, the bowl feeder stop working automatically, if not, the bowl feeder will start to work automatically. And at another side of the conveyor also keep another sensor for paper cores’ loading counting. Generally, they are used to keep the continuity of paper core transport to ensure every act of machine is valid and high precision.

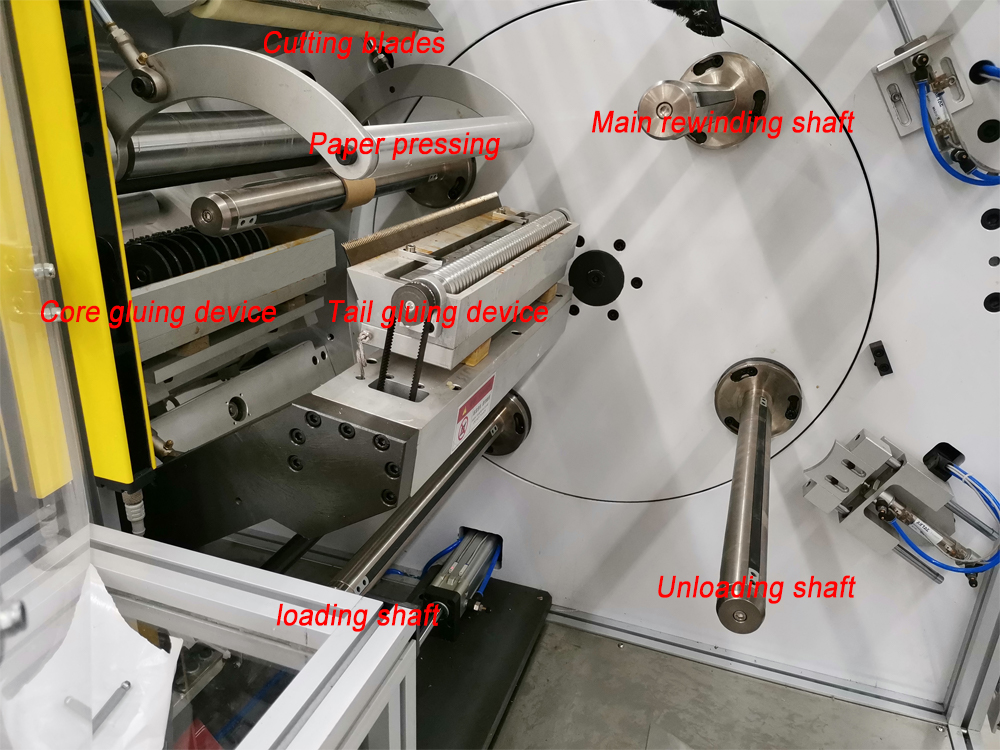

– Automatic core gluing system

For the glue-type turret, we attach the material to the core by hot melt glue.

– Air Shafts

l Quick-release Shafts: adopt four quick-release airshafts in daily working, according to the working sequence, one for paper core loading, two for rewinding, the last one is for unloading. Four shafts will go clockwise with the turning plate in the machine.

We have three sets of quick-release shafts:1’’,1.5’’,3’’(12 pcs) with the machine, or the size can be customized according to your requirements.

– Automatic gluing system:

We got two gluing systems in our machine, one for paper core gluing. Before rewinding, this system will glue two circles on the paper core, which allows the material to connect with the material.

l One is for tail gluing, when the rewinding is approaching the end, this system will inject a little glue in the surface of the material then a brush will go down and press the material so that we could seal the material.

l For the tail gluing part, we have an optional function of tail label sealing, use the label to seal the tail, so when the roll rewinding is finished, the labeling unit will go down and seal the roll with a label.

By the way, we also have a glue-free type with no glue on the core.(DBDG-4B)

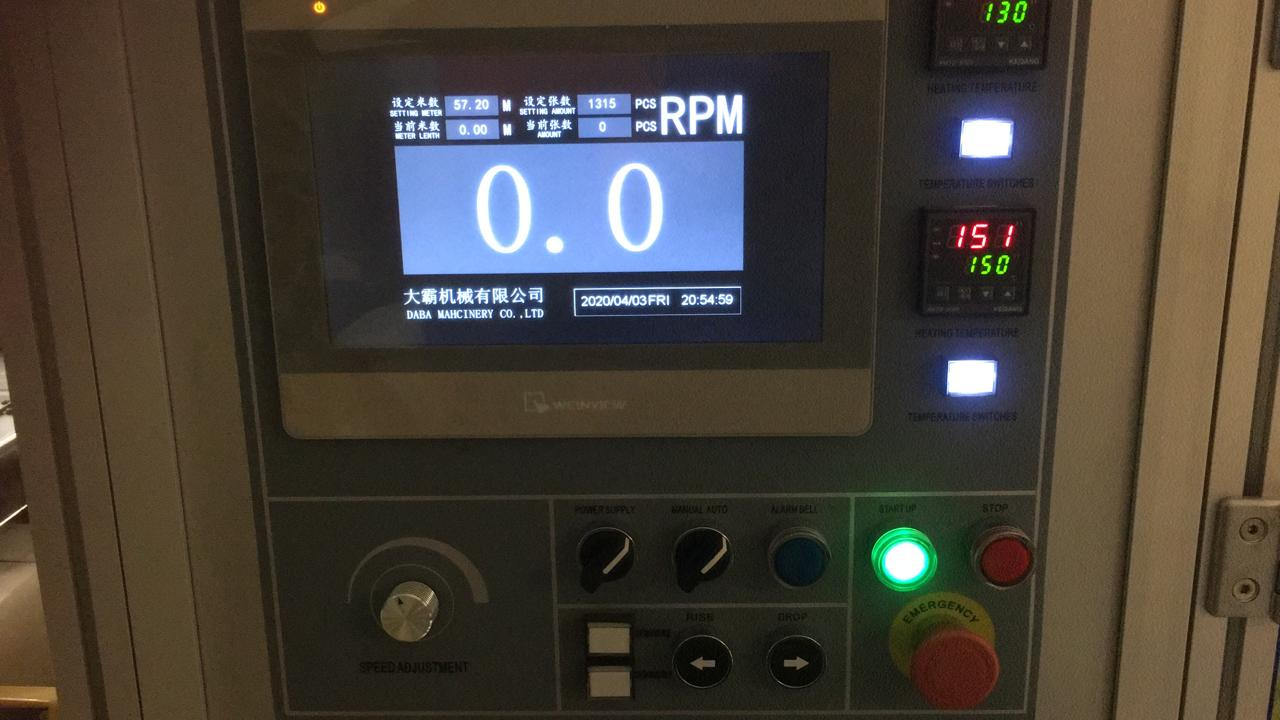

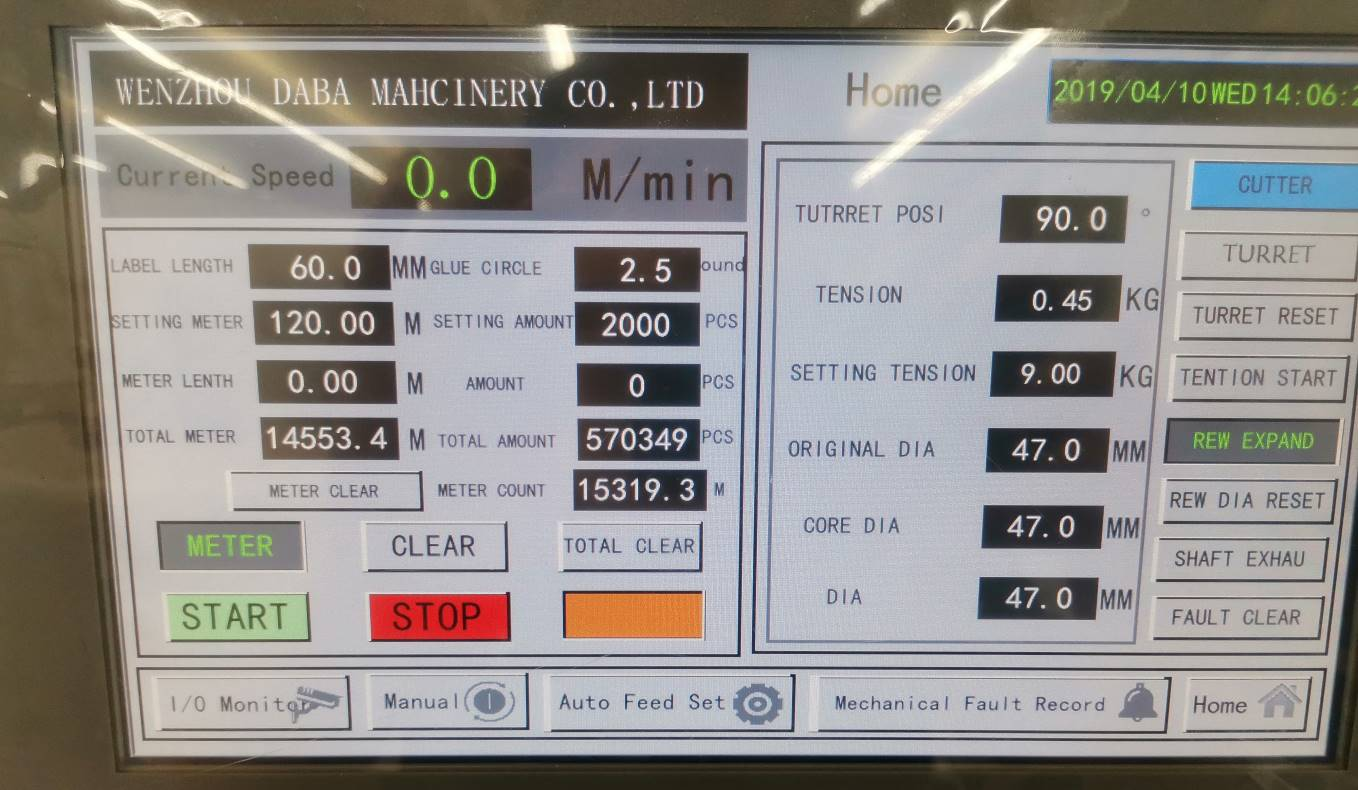

– Touch Screen

Briefness processes, don’t require specialized training to operate. If break down, there will be a fault item and description on the screen, you can check our manual and find a solution by yourself.