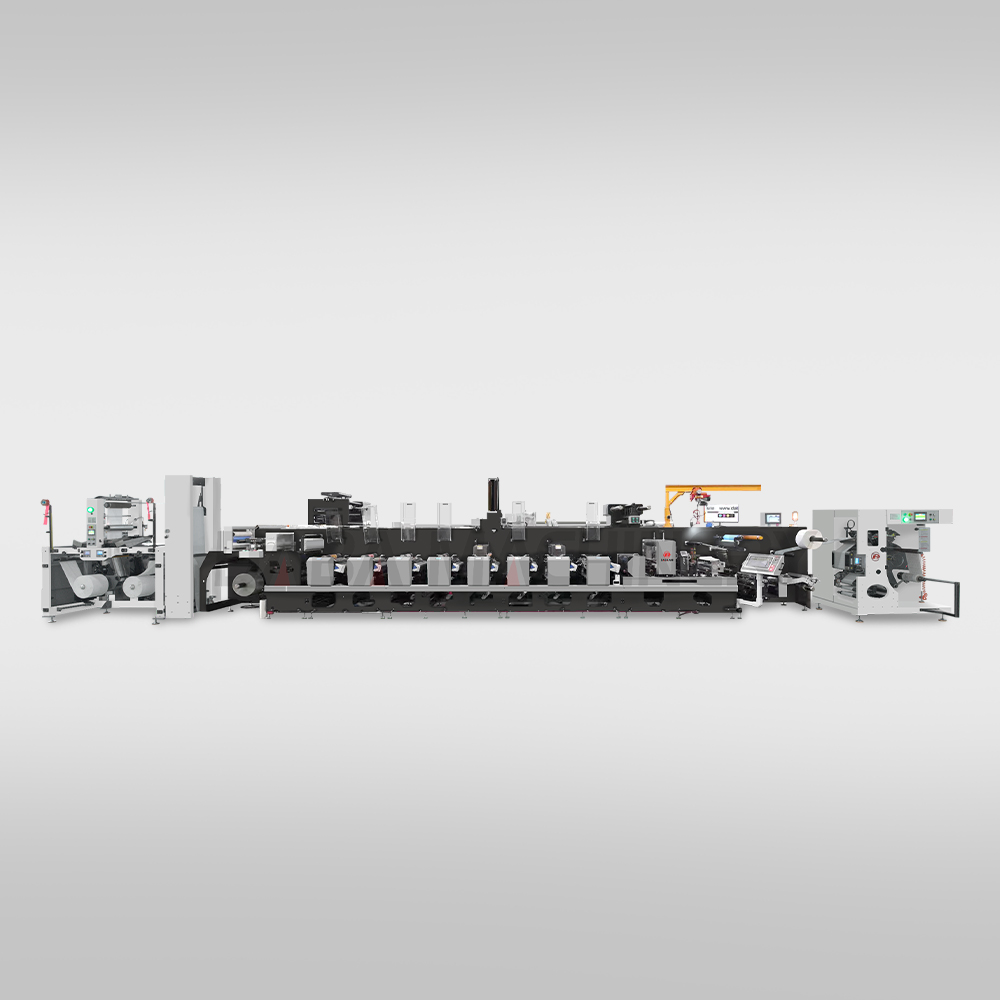

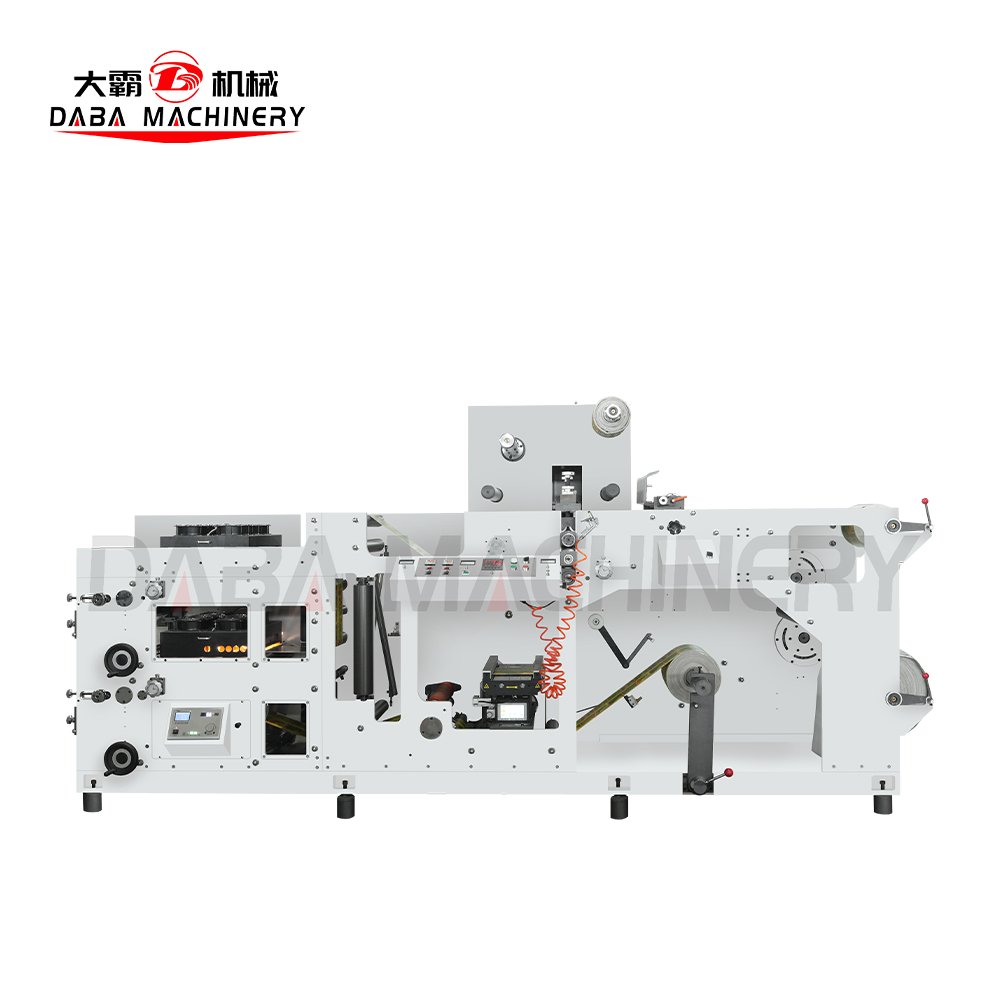

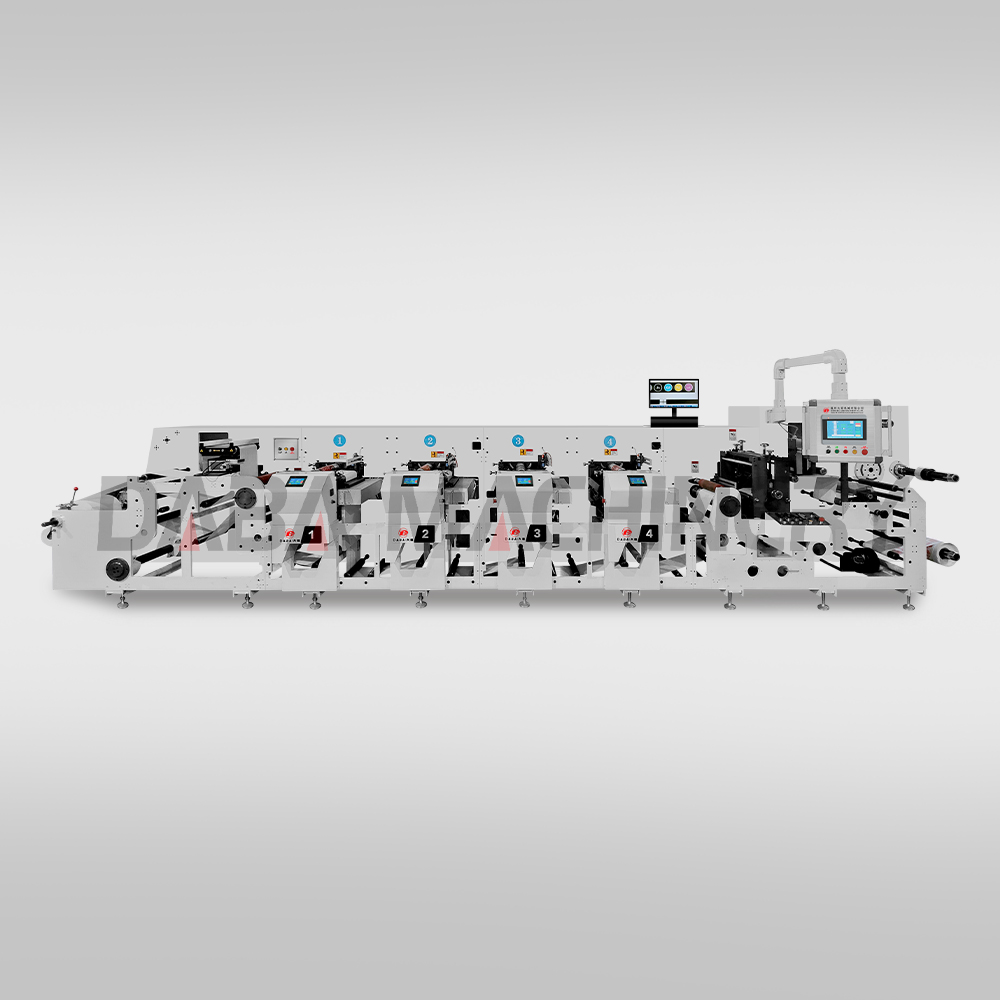

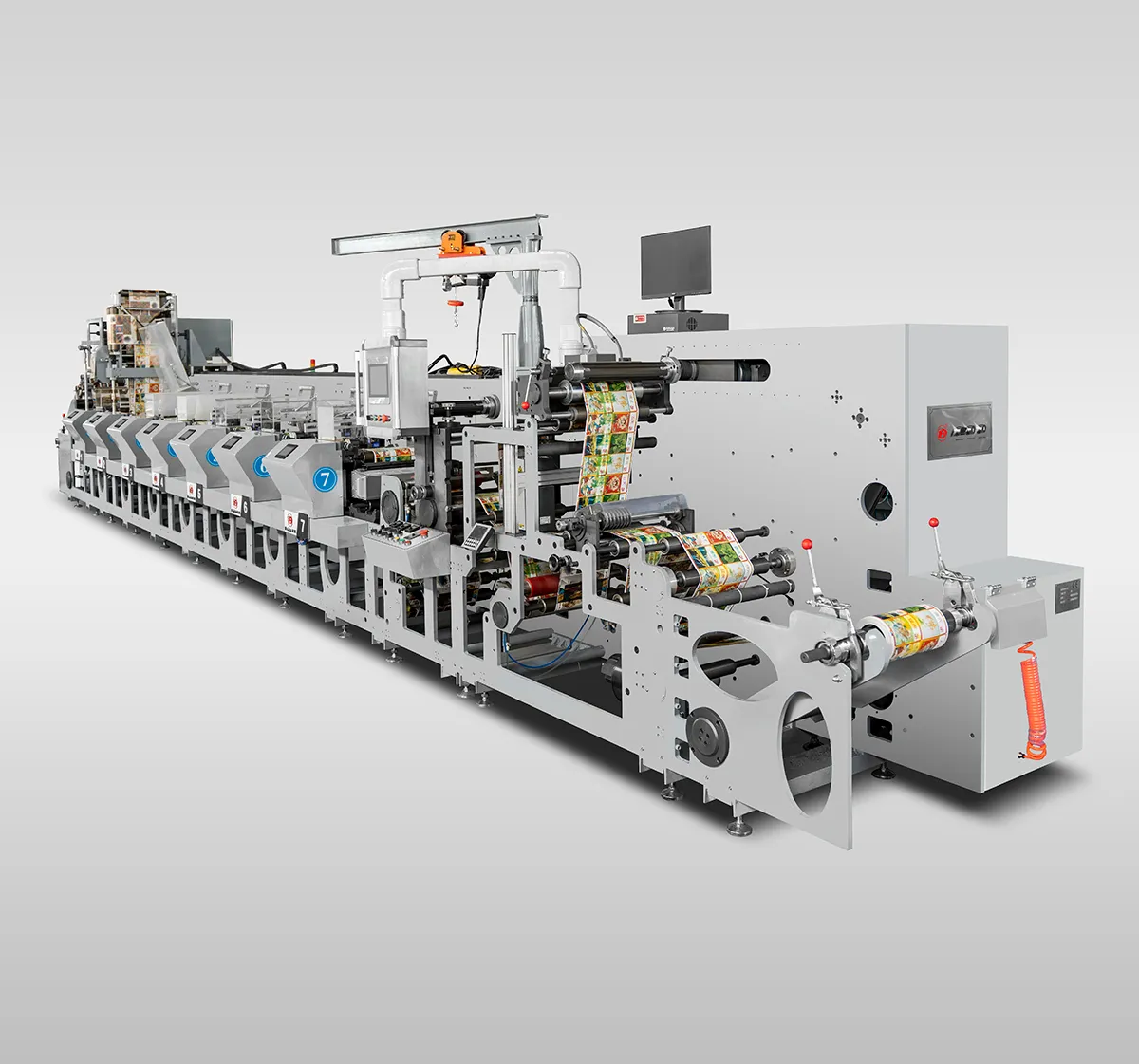

DBJY-320/450 Intermittent Label Offset Printing Press

OverView

High-performance servo-driven offset printing machine for commercial and packaging applications, featuring advanced automation and precision control systems.

Features

Fully Servo-Driven System

30+ servo motors synchronized control (3 per printing unit)±0.02mm repeat positioning accuracyCapable of 150 rpm high-speed printing

Intelligent Registration System

Dual registration

(pre-registration + fine-registration)

BST camera real-time monitoringAutomatic

lateral/longitudinal deviation compensation

Modular UV Drying

Independent LED UV system per printing unitAdjustable 3kW power40% lower energy consumption vs conventional drying

Quick Plate Change Technology

Automatic plate cylinder positioning <5 minute changeover timeMemory function stores 200+ job settings

Precision Ink Control

12-zone ink adjustment (25mm/zone)Remote ink density monitoringAutomatic viscosity control option

Continuous Production

1000mm max web diameterAuto tension control (±1%)

Smart HMI Interface

12.1" industrial touchscreenMulti-language supportReal-time fault diagnosis

Plug & Play Modules

Varnishing/cold foil/die-cutting units <30 minute module installationCentralized parameter control

Quality Assurance

100% print inspection systemDefect auto-markingProduction data traceability

Parameters

Basic Parameters

-

Max Printing Width

320mm/450mm

-

Printing Speed

150-180rpm

-

Material Thickness

0.02-0.5mm

-

Registration Accuracy

±0.05mm

-

Repeat Accuracy

±0.02mm

Unwinding/Rewinding

-

Max Diameter

Φ1000mm

-

Tension Control

Auto (±1%)

-

Shaft Type

3" airshaft

Printing System

-

Servo Motors

3 per unit

-

Ink Zones

12 zones (25mm each)

-

Drying

LED UV (3kW/unit)

Control & Automation

-

HMI

12.1" touchscreen

-

Job Memory

200+ presets

-

BST Camera Inspection

Real-time

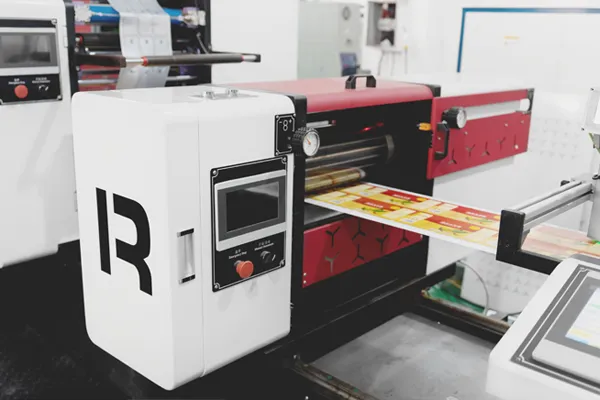

Cases

Details

FeedBack

Michael R., Premium Labels USA

"This 6-color press delivers perfect registration and vibrant colors. Reduced our waste by 30% and increased output - a game changer!"

Sarah L., Packaging Solutions UK

"The LED-UV drying is incredibly efficient. We've cut energy costs while achieving faster production speeds. Excellent investment!"

Thomas K., Global Print Germany

"Outstanding after-sales support! Their engineers resolved an urgent issue remotely in just 2 hours. Machine runs flawlessly."

FAQs

What materials can this press handle?

Handles paper, films, foils, and label stocks from 0.02-0.5mm thickness with precise tension control.

How does the registration system maintain accuracy?

Dual servo-driven registration with real-time camera monitoring and automatic compensation ensures ±0.05mm accuracy.

What makes your LED-UV system superior?

40% energy savings with instant curing and reduced heat damage to sensitive substrates.

Can the machine store job settings?

Yes, stores 200+ job presets including ink, registration, and drying parameters for quick changeovers.

How quick is job changeover?

Under 5 minutes with automatic plate cylinder positioning and preset recall.

What after-sales support do you provide?

Our certified engineers provide global on-site service within 72 hours, with 24/7 remote diagnostics.

Do you offer on-site training?

Yes, we provide 3-5 days comprehensive training at your facility worldwide, tailored to your operators.

How quickly can you respond to technical issues?

90% of issues resolved remotely within 4 hours via TeamViewer, with emergency on-site support available.

What's included in your warranty?

12 months on mechanical parts, 6 months on electrical components, with priority replacement service.

Can you service our machine locally?

We maintain a network of 50+ certified technicians across major markets for prompt local support.

What's the installation process?

Our engineers supervise installation (3-5 days) including calibration and test runs to ensure optimal performance.

How often does the machine need maintenance?

Recommended quarterly professional servicing with daily operator checks (lubrication, cleaning).

Do you provide maintenance training?

Yes, we train your staff on preventive maintenance procedures during commissioning.

Can we add modules later?

All options (varnish, foil, die-cutting) can be retrofitted with our engineering support.

Do you offer machine upgrades?

We provide periodic technology upgrades to keep your press current with industry advancements.

How does the quality control system work?

BST camera system performs 100% inspection with automatic defect marking and production data logging.

What's the maximum production speed?

150-180rpm with consistent quality (actual speed depends on substrate and design complexity).

What's the lead time for delivery?

8-12 weeks including factory testing and documentation preparation.

Do you provide spare parts globally?

Yes, with regional warehouses ensuring 48-hour delivery of critical components.

Can you help with machine relocation?

Our engineers can assist with professional dismantling, shipping, and reinstallation services.