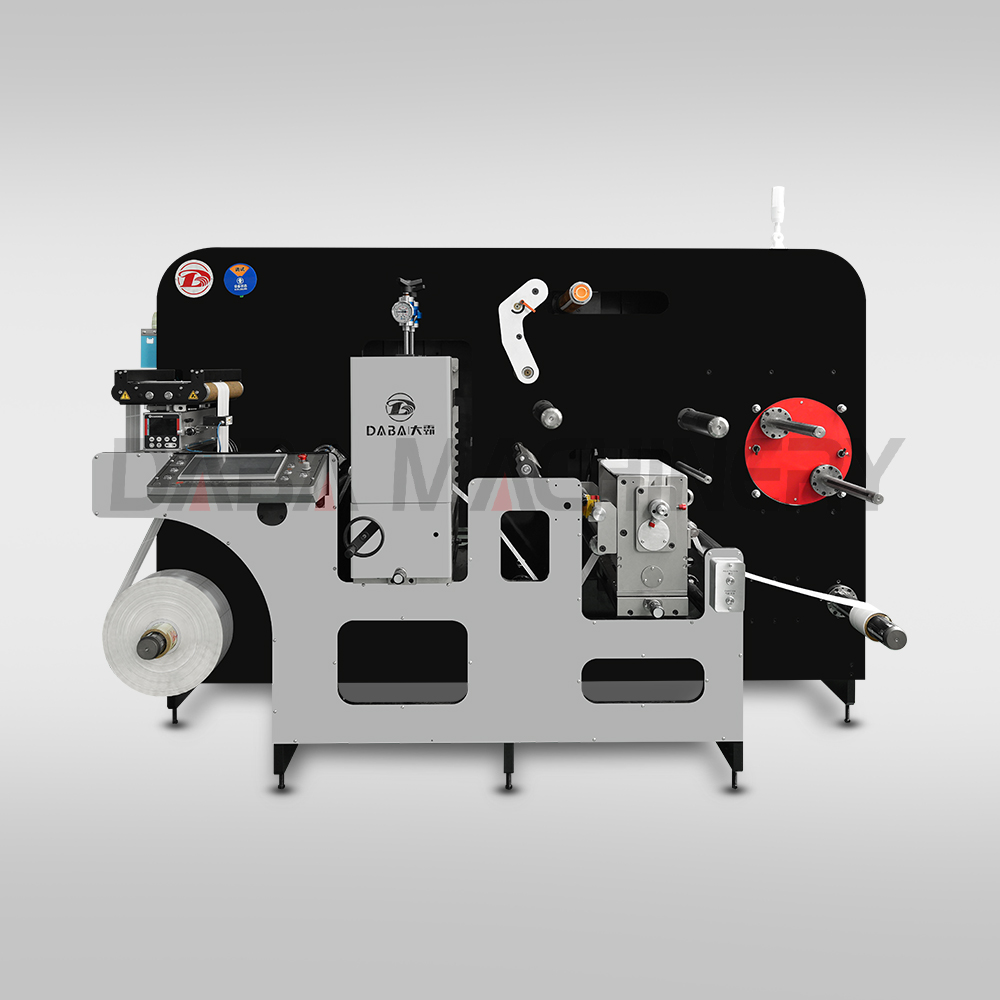

DBMQ-370 Semi Rotary Die Cutting Machine

Features

- ◪ Unwinding unit adopt photoelectric web guide system, with high precision. Control mode in two steps: manual and automatic

- ◪ Rewinding way: center coiling.

- ◪ The tension control of unwinding unit and rewinding unit is adopt automatic tension control system; the control modes are tension feedback control and taper control.

- ◪ The machine keep round cutter and flat cutter two tools, with reliable quality, easy to adjust.

- ◪ The slitter has fixed length automatic stop and the length meter automatically functions.

- ◪ The Slitter has trimming device, the edge material discharged by the fan.

Specifications

| Model | 370 | 470 |

| Capability | ||

| Max. web width | 370mm | 470mm |

| Max. unwinder/rewinder dia. | 800mm | 800mm |

| Web tickness | 30~300μm | 30~300μm |

| Max. rotary die cutting width | 370mm | 470mm |

| Max. full rotary die cutting speed | 120m/min | 120m/min |

| Max. intermittent die cutting speed | 60m/min | 60m/min |

| Die cutting precision(kiss cut) | ±0.15mm | ±0.15mm |

| Die cutting precision(through cut) | ±0.25mm | ±0.25mm |

| Max. slitting width | 370mm | 470mm |

| Dimensions & weight | ||

| Length | 3500mm | 3500mm |

| Width | 1700mm | 1800mm |

| Height | 1500mm | 1500mm |

| Weight | 2500kg | 2500kg |

| Power & Air | ||

| Voltage | AC 350v 50Hz 3PH | |

| Air source | 0.8MPa | |

3. Electrical Components

– Automatic Stop on Roll End

– Electronic Counter

– Pre-set Slowdown

– Electronic Web Guiding System and Ultrasonic Web Guide Sensor

– Servo Driven Infeed Unit

– Lamination Unit

– Automatic / Manual Die Cutting Registration System

– 1 Semi-rotary Die Cutting Station (it can be exchangeable between semi-rotary and full rotary die cutting)

◊ 1* 140T Magnetic Cylinder

– Slitting unit with 6sets circular knife / razor blade (according requirement)

– Touch Panel

– 2 Rewinding Unit

◊ up rewinding unit with on/off switch airshaft (with standard dia. 3inch)(OPTIONAL)

◊ down with single rewinding unit with on/off switch airshaft ( in 3inch )

◊ optional: up rewinding to be turret rewinding with 2 airshaft in size: 1inch or 1.5inch

◊ Max. Up rewinding dia.: 450mm, Max. Down rewinding dia.: 800mm

4. TECHNICAL APPENDIX

DBGS Label Die Cutting Machine (Rotary/intermittent type)

Features

The DBMQ Type Label Die Cutting Machine is aimed at the medium to long production runs and utilizes a single rotary die cutting station. The large 800mm unwind with taper tension control and electronic brake keeps roll changes to a minimum.

The DBMQ Label Die Cutting Machine compact size and short web path keeps wastage to a minimum, the fully adjustable silicone covered nip drive roller helps to keep down time to a minimum as labels cannot attach themselves to the roller. The DBMQ has accurate tension control through the use of an electronic unwind brake with taper tension control and the rewind is controlled through an electronic clutch. A splice table makes web splices both simple and quick. Quick change air mandrels for the product rewind ensures that cores a gripped firmly and a production speed of 120m/minute.

· Web width 450mm

Standard Features

· Unwind

o Maximum unwind diameter: 800mm (31.5″).

o 76mm (3″) air mandrel.

o Merobel electromagnetic particle brake.

o Taper tension control – No roll-followers or external sensors to be adjusted or maintained.

· Splice Table- Makes web splicing easier and quicker.

o Pneumatic web clamps.

· Die Station

o 190 – 666.75mm die repeats.

o 666.75 Max Full Rotary

o hardened anvil – 120T

o Magnetic Cylinder – 140T –repeat

o Gearing – 1/8 cp, 20 degree pressure angle.

o A driven capstan roller with adjustable tension control ensures reliable matrix stripping, enabling high speed running even if the matrix rewind becomes unstable.

o Matrix / Waste Rewind – 600mm diameter with fully adjustable tension control.

o 76mm (3″) mechanical mandrel for waste rewind.

· Slitting Station

o With 6sets circular knife or razor blade

o With automatic suction waste matrix

o With scaled roller for slitting width adjustion by manual

· Draw Head

o Silicone nip roller against a driven draw roller.

o The silicone nip roller does not allow labels to attach themselves to it reducing down time.

o Fully adjustable to allow for different label stocks.

o The draw roller is driven by a 1.8 Kw servo motor.

· Rewind

o Maximum rewind diameter: 800mm

o 76mm (3″) quick change air mandrel.

o Label in / labels out rewinding.

o Electromagnetic particle clutch. 5 KG

· Intermittend Die Cutting Speed- 60 meters/Min

· Conforms to CE regulations and all circuits use dual channel safety switches, which are continuously monitored using a certified safety relay.

Configuration List

Name | Model Brand | Manufacture |

Main Control System | INOVANCE system | China |

Powder Clutch | Shengda | China |

Web Guiding | RE | Italia |

Servo Motors | Inovance | China |

Sensors | LEUZE | Germany |

Touch Screen | Kinco | China |

Reducer | SHIMPO | Japan |

Electric components | Schneider | Germany |

Gears&Bearings | NSK | Japan |

Screws | 12.9 Levels | |

Magnetic Cylinder | Rotary 200 T | |

Power Switch | Schneider | Germany |

Pneumatic Switch | Schneider | Germany |

Switch | Schneider | Germany |

Random Accessories

Hexagon | 1 set |

10 “adjustable wrench | 1 pecs |

6″adjustable wrench | 1 pecs |

1 pecs | |

Belt | 2 pecs |

Air gums | 1 pecs |

Magnetic Cylinder Supporter | 3 Pecs |

Button | 5 Pieces |